Best Manufacturing ERP Software: Top 10 for Efficiency

Compare the top ERP solutions for manufacturing . Find the right platform to streamline production, reduce costs, and scale operations.

Table of Contents

- ☑️ What Is Manufacturing ERP & Why Every Factory Needs It

- ☑️ ERP essential features for manufacturing environments

- ☑️ Top 10 Manufacturing ERP Systems (Ranked & Compared)

- 1️⃣ SAP S/4HANA

- 2️⃣ Oracle NetSuite ERP

- 3️⃣ Epicor Kinetic

- 4️⃣ Infor CloudSuite Industrial

- 5️⃣ Microsoft Dynamics 365 Supply Chain

- 6️⃣ Acumatica Manufacturing

- 7️⃣ SAP Business One

- 8️⃣ SYSPRO

- 9️⃣ Plex ERP

- 🔟 Odoo

- 🔷 YouConclude: Which Is Right for Your Business?

- ✓ YouConclude More

-

☑️ What Is Manufacturing ERP & Why Every Factory Needs It

Manufacturing ERP software isn’t just another IT upgrade — it’s the digital backbone of modern production. As global supply chains become more volatile and customer demands accelerate, ERP solutions for manufacturing provide the only scalable way to synchronize materials, machines, and manpower in real time. From shop floor control to multi-site forecasting, these systems help manufacturers increase output, reduce waste, and maintain quality — all while staying lean.

Let’s unpack the full picture, from what it really is to why it’s mission-critical across industries today.

→ What is ERP for manufacturing?

Manufacturing ERP (Enterprise Resource Planning) refers to a suite of integrated business applications designed specifically for production environments. Unlike generic ERPs, manufacturing-focused systems go beyond finance and HR to support:

-

Bill of Materials (BOM) management

-

Routing and scheduling

-

Material Requirements Planning (MRP)

-

Shop floor control and work center tracking

-

Inventory visibility by location, lot, and serial number

-

Vendor and procurement automation

-

Production cost analysis and variance tracking

It connects departments like production, purchasing, inventory, finance, and sales under one unified data system — ensuring a single source of truth across the entire manufacturing lifecycle.

→ Core pain points ERP systems solve on the production floor

Manufacturers face specific, high-stakes challenges that only purpose-built ERP systems can address at scale:

-

🔄 Manual planning chaos: Siloed spreadsheets and outdated tools delay orders and misallocate materials.

-

❌ Unplanned downtime: Without predictive scheduling, machine breakdowns disrupt output.

-

📦 Inventory distortion: Overstocking or stockouts both damage margin and delivery reliability.

-

👷 Labor misalignment: Without work center insight, staffing is either under- or over-assigned.

-

🧾 Compliance burdens: Industry-specific standards (FDA, ISO, AS9100, etc.) demand granular audit trails.

-

📉 Lack of real-time visibility: Decision-makers can't act fast when data is scattered across departments.

A solid ERP replaces chaos with clarity.

→ Why traditional tools fall short in modern supply chains

Legacy software like accounting programs, spreadsheets, and even entry-level MRP systems were not built for the speed, complexity, or regulatory demands of modern manufacturing.

Problems with outdated tools include:

-

No real-time shop floor integration

-

Inaccurate forecasting and slow reactivity to supply changes

-

Manual data entry across departments (error-prone and costly)

-

Poor coordination between engineering and production

-

Inflexible to custom workflows or advanced manufacturing modes

As product lifecycles shorten and supply disruptions rise, manufacturers without ERP systems lose agility and miss profit opportunities.

→ How ERP solutions improve visibility, cost control, and lead time

Modern ERP systems for manufacturing give leadership the tools to act decisively across multiple fronts:

-

Production planning becomes demand-driven, not guesswork.

-

Real-time dashboards show OEE (Overall Equipment Effectiveness), cycle times, and work order progress.

-

Inventory control is dynamic — auto-replenishing raw materials just-in-time.

-

Cost accounting links labor, machine hours, and materials to each job or part.

-

Lead time shrinks with coordinated procurement, assembly, and shipping.

These advantages ripple throughout the operation — boosting fulfillment rates, reducing excess inventory, and improving cash flow.

→ Where manufacturing ERP fits into digital transformation

Manufacturing ERP is the foundation layer of digital transformation in factories. It's what enables the integration of:

-

MES (Manufacturing Execution Systems) for machine-level monitoring

-

IIoT devices for real-time equipment and sensor data

-

Advanced analytics & AI-driven scheduling

-

End-to-end traceability from supplier to customer

-

Customer portals with accurate status updates and self-service

Companies that delay ERP adoption often find themselves stuck — unable to roll out higher-value digital projects due to fragmented data and legacy infrastructure.

-

-

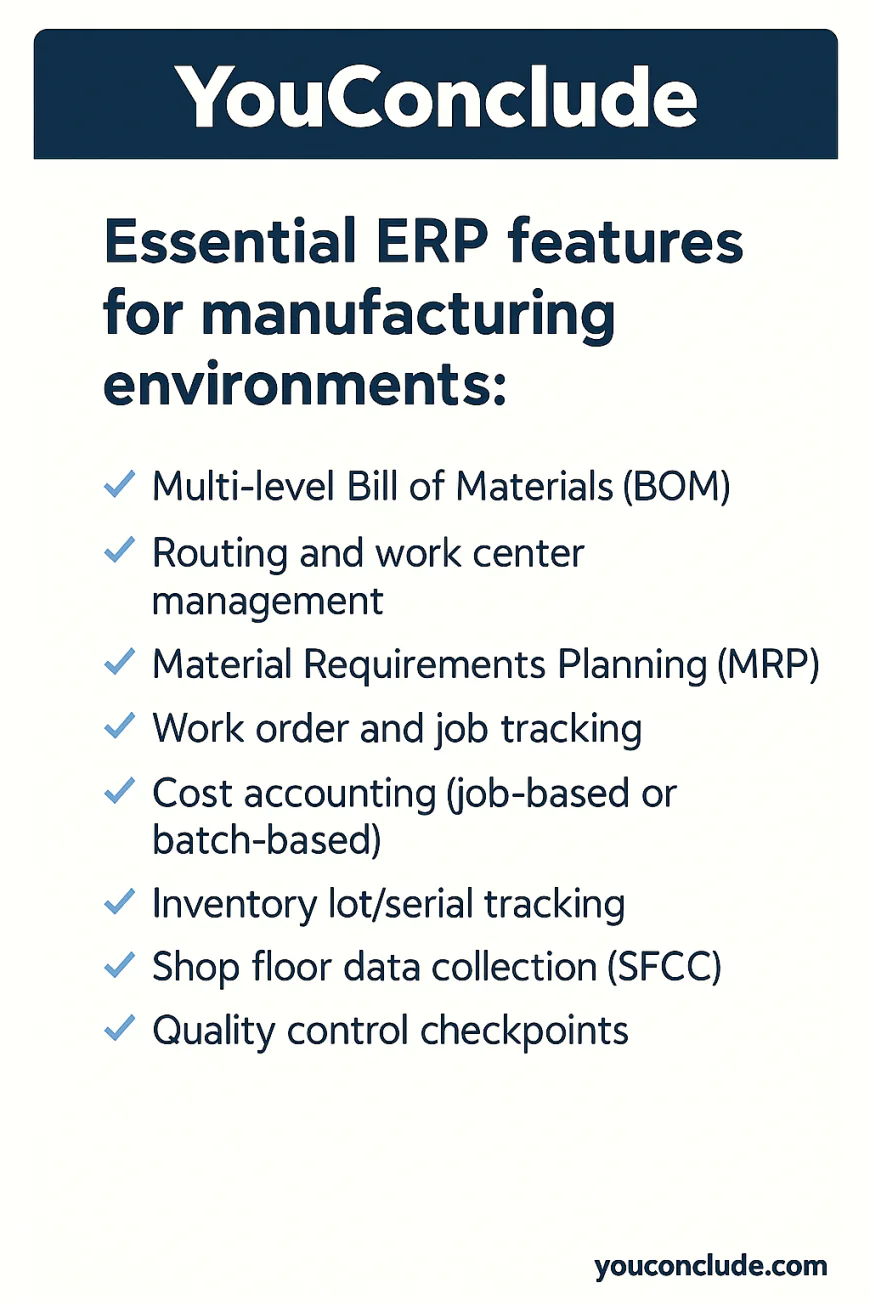

☑️ ERP essential features for manufacturing environments

What ERP features are absolutely essential for manufacturing environments?

Manufacturers can’t rely on generic ERP modules. The system must support operations that happen on the shop floor — not just in the office.

Here are the foundational ERP features required for any serious manufacturing use case:

-

Multi-level Bill of Materials (BOM): For full control over assemblies, sub-assemblies, and component dependencies.

-

Routing and work center management: Define specific machine paths, cycle times, and labor allocations per operation.

-

Material Requirements Planning (MRP): Time-phased material planning that syncs with BOMs and sales orders.

-

Work order and job tracking: Create, release, and monitor WIP (Work In Progress) in real time.

-

Cost accounting (job-based or batch-based): Accurate breakdown of material, labor, and overhead per order or SKU.

-

Inventory lot/serial tracking: For precise traceability of raw and finished goods — critical in regulated industries.

-

Shop floor data collection (SFDC): Touchscreen or scanner-based input for labor, scrap, downtime, etc.

-

Quality control checkpoints: Embedded QC workflows that trigger at defined stages (inbound, in-process, final).

Without these, you're not running a manufacturing ERP — you’re just customizing a finance tool.

Should manufacturers choose a cloud ERP or on-premise deployment?

There’s no one-size-fits-all — but the shift is clearly toward cloud ERP, even in plant environments.

Cloud ERP advantages:

-

📡 Remote access: Operations, maintenance, and supervisors can access dashboards anywhere.

-

🔄 Automatic updates: Always using the latest software version — no IT patching.

-

💸 Lower upfront cost: Subscription-based pricing vs infrastructure investment.

-

🛡️ Disaster recovery: Data backed up and mirrored across data centers.

But on-premise may still be preferred if:

-

🌐 Internet is unstable or bandwidth is insufficient on the plant floor.

-

🔒 IT/security policies restrict external hosting (e.g., aerospace defense contractors).

-

⚙️ Custom machinery integration requires deep local API or edge-computing support.

Hybrid cloud + edge solutions are emerging fast — many ERPs today offer modular hosting flexibility to handle this split.

How important is regulatory compliance and usability at the plant level?

Crucial. Manufacturing ERPs must address both external compliance and internal operational control:

Regulatory needs:

-

⚖️ GMP, ISO 9001, FDA (21 CFR Part 11): Built-in documentation trails, e-signatures, and audit logs.

-

🔍 Lot/serial traceability: From raw material to shipment — with instant backward recall ability.

-

🧾 Certificate of Analysis (COA) handling: Automated quality result tracking.

Usability needs:

-

👷 Role-based UIs: Operators shouldn’t see finance modules; planners need quick drag-and-drop rescheduling.

-

📱 Mobile/tablet access: Line supervisors update production status on the floor — not at a desktop.

-

⚙️ Touchscreen-friendly SFDC: Reduce training overhead and manual entry errors.

If your ERP adds friction instead of removing it, you’re not improving throughput — you’re just digitizing bureaucracy.

What other systems must ERP integrate with on the shop floor?

A real manufacturing ERP system doesn’t operate in isolation. It must serve as the data backbone between:

-

MES (Manufacturing Execution System): Real-time production control, machine status, and performance KPIs.

-

SCADA systems: Pull equipment runtime, alerts, sensor status, etc.

-

Inventory & warehouse systems (WMS): Bin-level accuracy, pick-pack rules, reorder automation.

-

Procurement platforms: Automate POs, supplier lead time tracking, and delivery confirmations.

-

PLM/CAD software: Ensure version-controlled BOMs and specs move from design to production.

Some ERPs include MES modules; others integrate through APIs. Evaluate whether your vendor offers native integrations or requires third-party middleware.

Should discrete and process manufacturers choose different ERPs?

Absolutely — the manufacturing mode drives core ERP design.

Discrete manufacturers (automotive, electronics, machinery):

-

Need: Routings, finite scheduling, part-level serial tracking.

-

Require: CAD/PLM integration, revision control, complex BOMs.

-

Example ERP fit: Epicor Kinetic, Microsoft D365, Infor CSI

Process manufacturers (chemicals, food, pharma):

-

Need: Recipes/formulas, batch processing, yield management.

-

Require: Lot traceability, potency tracking, compliance-heavy QC.

-

Example ERP fit: BatchMaster ERP, Deacom, Aptean Process Manufacturing

Some systems claim “mixed-mode” support — but unless built natively, most lean heavily toward one mode. Choose accordingly.

-

-

☑️ Top 10 Manufacturing ERP Systems (Ranked & Compared)

-

1️⃣ SAP S/4HANA

Enterprise-grade control for complex global manufacturers

▪️ What is SAP S/4HANA and why is it ideal for global-scale manufacturing?

SAP S/4HANA is a real-time ERP suite built on the HANA in-memory database, designed to handle multi-plant, multi-country, multi-product manufacturing operations. It supports end-to-end processes, from procurement and production planning to advanced warehouse and transportation management, tailored for high-complexity manufacturers in industries like aerospace, automotive, and pharmaceuticals.

It’s not just software — it’s a full operational ecosystem that enables mass customization, real-time supply chain orchestration, and predictive analytics at scale.

▪️ What core manufacturing features does SAP S/4HANA offer?

-

Advanced Planning & Scheduling (APS): Built-in PP/DS (Production Planning/Detailed Scheduling) with real-time ATP (Available to Promise).

-

Integrated Quality Management (QM): Ensures compliance and traceability across global sites.

-

Embedded MES capabilities: Through Digital Manufacturing Cloud (DMC) integration for execution visibility.

-

Engineering Change Management: Handles BOM/versioning across global product lines.

-

Co-product and by-product management: For complex process industries like chemicals or food.

▪️ How does SAP S/4HANA integrate across a manufacturing enterprise?

SAP S/4HANA seamlessly connects with:

-

SAP Digital Manufacturing Cloud (DMC) for MES-level execution.

-

SAP Extended Warehouse Management (EWM) and SAP Transportation Management (TM).

-

IoT platforms and machine-level automation systems via Industry 4.0 extensions.

-

PLM and CAD tools via SAP Engineering Control Center (ECTR).

-

Third-party apps via SAP BTP (Business Technology Platform).

It ensures that supply chain planning, asset performance, and customer demand are all synchronized in real time.

▪️ What are some real-world examples of SAP S/4HANA in manufacturing?

-

Siemens uses S/4HANA to run 100+ global production plants, unifying engineering data, production schedules, and inventory in real time.

-

BASF deploys S/4HANA for compliance-heavy chemical manufacturing, enabling auditable batch tracking and complex co-product calculations.

-

Danfoss (HVAC) cut lead times by 30% and reduced production rework by integrating S/4HANA with shop-floor automation systems.

These are companies that operate millions of SKUs, thousands of suppliers, and need sub-second decision-making.

▪️ What do real enterprise users say about SAP S/4HANA?

🌟 What users love:

-

Massive flexibility across countries, divisions, and business models.

-

High performance and fast data retrieval, even in huge datasets.

-

Powerful financial integration — great for cost center-level control.

⚠️ Areas for improvement:

-

Complex initial implementation; not plug-and-play.

-

Requires strong internal IT team or external SAP consultants.

-

Customization can create long-term upgrade complexity if not carefully managed.

Most users agree it delivers unmatched control — but only if you're equipped for its scale.

▪️ Where can I learn more or get SAP S/4HANA officially?

You can explore the full features, case studies, and deployment paths on the official SAP S/4HANA website.

-

-

2️⃣ Oracle NetSuite ERP

Best cloud-native ERP for scaling manufacturers

▪️ What is NetSuite ERP and why is it popular with growing manufacturers?

Oracle NetSuite is a true cloud-native ERP designed for fast-growing manufacturers, especially those scaling beyond spreadsheets or legacy systems. It unifies financials, production planning, inventory, order management, and procurement — all in one platform.

It's especially powerful for multi-channel manufacturers dealing with high product variability, complex BOMs, and rapid expansion across facilities or countries. Its modular, SaaS-based design also means low infrastructure cost and high deployment speed.

▪️ What key manufacturing features does NetSuite offer?

-

Work Orders & Assemblies: Track labor, parts, and components for discrete manufacturing.

-

Bill of Materials (BOM) + multi-level routings.

-

Demand Planning & MRP: Reorder points, forecast-driven planning, and allocation.

-

Production Scheduling: Drag-and-drop Gantt charts with shop calendar integration.

-

WIP & Costing: Track actual vs standard cost at job level.

-

Shop Floor Control: Real-time tracking of work orders and labor usage (SuiteApp add-ons).

It’s optimized for make-to-stock, assemble-to-order, and light custom manufacturing.

▪️ How does NetSuite ERP integrate with other systems and platforms?

NetSuite offers powerful integration options:

-

Built-in API and SuiteTalk (SOAP and REST) for custom integrations.

-

NetSuite Connector for Shopify, Amazon, Magento, WooCommerce.

-

Native CRM, WMS, HR, and eCommerce within the NetSuite ecosystem.

-

Integrates with CAD/PLM platforms via partners like Arena or Propel.

-

Compatible with IoT/MES layers through Boomi and Celigo middleware.

Its all-in-one ecosystem makes it especially attractive to growing manufacturers wanting less IT overhead.

▪️ What are some real-world use cases of NetSuite in manufacturing?

-

Rothy’s (sustainable fashion manufacturer) uses NetSuite for global supply chain visibility and production management.

-

T3 Micro (electronics manufacturing) centralized financials, order management, and manufacturing into one platform to support rapid growth.

-

Hydrow (fitness manufacturing) reduced their manual fulfillment errors and scaled D2C + B2B channels on NetSuite’s unified system.

NetSuite is popular in industries like consumer goods, electronics, medical devices, and light assembly.

▪️ What do real SMB and mid-market users say about NetSuite ERP?

🌟 What users love:

-

Unified view of operations with finance and inventory tightly connected.

-

Fast deployment (3–6 months typical) and frequent cloud updates.

-

Ideal for multi-location or global manufacturers.

⚠️ Areas for improvement:

-

Requires trained consultants for customization.

-

Some limitations in deep process manufacturing (e.g., chemical formulas).

-

Advanced features can become expensive via SuiteApp ecosystem.

Most users say it delivers exceptional value once tailored correctly to manufacturing workflows.

▪️ Where can I learn more or try Oracle NetSuite ERP?

You can explore official demos, pricing options, and implementation services on the Oracle NetSuite ERP website.

-

-

3️⃣ Epicor Kinetic

Discrete manufacturing specialist (machining, automotive)

▪️ What makes Epicor Kinetic ideal for discrete manufacturers?

Epicor Kinetic is purpose-built to support complex discrete manufacturing environments such as machining, automotive, aerospace, and industrial equipment. It focuses heavily on shop floor control, precision scheduling, and quality management.

Its strengths lie in managing engineer-to-order and make-to-order workflows with detailed tracking of materials, labor, and machine time — critical for parts manufacturing where precision and traceability matter.

▪️ What key features does Epicor Kinetic offer manufacturers?

-

Advanced scheduling: Finite capacity scheduling, drag-and-drop scheduling boards.

-

BOM and routing management: Supports complex multi-level BOMs with variant configurations.

-

Quality Management System (QMS): Integrated inspections, non-conformance tracking, and corrective actions.

-

Shop Floor Data Collection (SFDC): Real-time labor and machine data capture.

-

Inventory & warehouse management with lot and serial tracking.

-

Document management and full traceability.

-

Manufacturing Intelligence dashboards for OEE, downtime, and productivity metrics.

▪️ How does Epicor Kinetic integrate with other business systems?

Epicor supports a wide range of integrations via:

-

Native connectors to popular MES, CRM, and PLM systems.

-

Open REST APIs for custom integrations.

-

Integration with Microsoft Office and Power BI for reporting.

-

Cloud or hybrid deployment options for flexible IT environments.

▪️ Can you share some real-world manufacturing use cases?

-

Harley-Davidson uses Epicor to streamline production and quality for their motorcycle assembly lines.

-

Roland DG (digital printing equipment) optimized inventory and shop floor operations with Epicor.

-

Horseshoe Manufacturing increased throughput and reduced scrap by leveraging Epicor’s advanced scheduling.

▪️ What do users typically praise or criticize about Epicor Kinetic?

🌟 Positives:

-

Highly customizable for complex discrete manufacturing.

-

Strong shop floor control and quality management.

-

Good visibility into production KPIs.

⚠️ Challenges:

-

Steep learning curve for new users.

-

Implementation can be lengthy and costly.

-

User interface considered dated by some.

▪️ Where can I find more info or request a demo?

Visit the official Epicor Kinetic site here: Epicor Kinetic.

-

-

4️⃣ Infor CloudSuite Industrial

Engineer-to-order (ETO) specialist

▪️ Why is Infor CloudSuite Industrial ideal for engineer-to-order manufacturers?

Infor CloudSuite Industrial (also known as SyteLine) is tailor-made for engineer-to-order (ETO) and configure-to-order (CTO) manufacturers who deal with complex, custom-built products and long production cycles. It excels in scenarios where every order is different and must be engineered, priced, and scheduled on demand — such as industrial equipment, aerospace, and electronics.

Its tight alignment with project-based manufacturing workflows makes it a standout in industries that require exacting cost control, BOM variation, and real-time engineering collaboration.

▪️ What are the most critical manufacturing features in Infor CloudSuite?

-

Multi-site, multi-entity ERP for global manufacturing and supply chains.

-

Project lifecycle management integrated with engineering and financials.

-

Dynamic BOMs and configuration tools to support variable designs.

-

Advanced Planning & Scheduling (APS) with finite capacity modeling.

-

Integrated CAD/PLM tools to connect engineering changes to production.

-

Field service and warranty tracking for asset-based industries.

-

Role-based workbenches and factory floor user interfaces.

▪️ How well does Infor integrate with other manufacturing systems?

Infor CloudSuite offers flexible integrations via:

-

ION middleware for connecting with other ERP, CRM, and MES platforms.

-

Out-of-the-box integrations with AutoCAD, SolidWorks, and PTC Windchill.

-

Seamless connection with Infor OS for workflow automation and AI.

-

Native reporting through Birst BI and Microsoft Power BI.

▪️ Real-world manufacturing examples of Infor CloudSuite?

-

Thermo Fisher Scientific uses Infor CloudSuite Industrial to manage complex production workflows across global operations.

-

Hytrol Conveyor Co. runs engineer-to-order assembly lines with project-driven MRP and integrated CAD tools.

-

National Oilwell Varco (NOV) relies on it for scalable, ETO-style operations across dozens of international sites.

▪️ What do manufacturers love and critique about Infor CloudSuite?

🌟 Positives:

-

Strong ETO and project-centric workflow support.

-

Excellent product configuration and cost control.

-

Rich industry-specific functionality for industrial and aerospace sectors.

⚠️ Challenges:

-

Interface and navigation can feel dated compared to newer platforms.

-

Performance can lag in large deployments without proper tuning.

-

Some modules (e.g., field service) require additional licensing.

▪️ Where’s the official product page for more info?

Visit the official Infor CloudSuite Industrial page here:

🔗 Infor CloudSuite Industrial (SyteLine)

-

-

5️⃣ Microsoft Dynamics 365 Supply Chain

Mixed-mode manufacturing powerhouse

▪️ What makes Microsoft D365 Supply Chain a top ERP for manufacturers?

Microsoft Dynamics 365 Supply Chain Management (part of the broader D365 ERP suite) is designed to handle mixed-mode manufacturing, which means it supports discrete, process, and lean production models in a single platform. It’s widely used by manufacturers that need real-time insight into inventory, logistics, shop floor control, and demand forecasting — all while staying agile in global supply networks.

This ERP is especially strong for mid-market to large enterprises that want tight integration with Microsoft tools and a modular architecture they can scale.

▪️ Which core manufacturing features does D365 Supply Chain offer?

-

Advanced production control: support for discrete, process, lean, and batch manufacturing.

-

Integrated warehouse & transportation management (WMS/TMS).

-

Predictive maintenance & IoT via Azure integration.

-

Real-time shop floor insights with OEE and downtime tracking.

-

Integrated quality management & compliance tools.

-

Global financial and tax compliance in over 40 countries.

-

Built-in AI and machine learning for demand forecasting and inventory optimization.

▪️ How well does D365 Supply Chain integrate with other systems?

It’s built on Microsoft’s Power Platform and integrates tightly with:

-

Microsoft 365 apps (Excel, Teams, Outlook, etc.)

-

Power BI, Power Automate, and Dataverse for analytics and automation.

-

Azure IoT, Azure ML, and Dynamics Field Service.

-

MES systems, barcode scanners, RFID, and SCADA through custom connectors or APIs.

▪️ Real-world manufacturers using D365 Supply Chain?

-

Peet’s Coffee automates its roasting and distribution process using D365 SCM for better traceability and cost control.

-

ZF Group leverages it for real-time inventory and global parts tracking.

-

Bel Fuse Inc. utilizes it to streamline high-volume electronics assembly across multiple plants.

▪️ What do real users say about Dynamics 365 for manufacturing?

🌟 Positives:

-

Rich, modular architecture that grows with your business.

-

Strong data visibility and reporting with Power BI built-in.

-

Excellent for companies already using Microsoft ecosystems.

⚠️ Challenges:

-

Can be complex to implement and optimize without a certified partner.

-

Some learning curve for manufacturing floor teams without prior ERP exposure.

-

Requires fine-tuning to get best performance in highly customized workflows.

▪️ What’s the official site for Microsoft D365 Supply Chain?

🔗 Microsoft Dynamics 365 Supply Chain Management

-

-

6️⃣ Acumatica Manufacturing

Modern ERP for growing mid-market firms

▪️ Why is Acumatica a strong choice for manufacturers?

Acumatica Manufacturing Edition is a cloud-native ERP built for flexibility and scalability, ideal for mid-sized manufacturers who want modern tech without the overhead of legacy systems. Unlike older platforms, Acumatica is designed for real-time operations, mobile accessibility, and fast deployment — making it highly attractive to discrete, job shop, and batch manufacturers.

It’s especially popular with firms that have outgrown QuickBooks and want an end-to-end system that includes production, inventory, finance, CRM, and distribution in one unified solution.

▪️ What manufacturing-specific features does Acumatica offer?

-

Bill of Materials (BOM) and Routing management

-

Production scheduling and MRP (Material Requirements Planning)

-

Shop floor data collection and labor tracking

-

Quality control and lot/serial traceability

-

Work orders, vendor management, and order costing

-

Advanced planning and what-if scenarios

-

Multi-site, multi-warehouse inventory tracking

▪️ What systems and tools does Acumatica integrate with?

-

CAD and PLM systems via API or middleware

-

Shop floor and barcode scanning tools

-

eCommerce platforms like BigCommerce and Shopify

-

CRM modules (native or external)

-

Power BI, Excel, and Tableau for advanced analytics

-

Integrates with shipping, procurement, and payroll software

▪️ What real-world manufacturers use Acumatica?

-

Fulton Industries, a manufacturer of emergency lighting systems, used Acumatica to centralize BOMs and streamline project costing.

-

Korpack, a packaging manufacturer, consolidated finance, warehouse, and assembly operations after switching from fragmented legacy tools.

-

Firewire Surfboards, based in California, leverages Acumatica to manage global sourcing and product lifecycles.

▪️ What do real users say about Acumatica for manufacturing?

🌟 Positives:

-

Affordable pricing structure with unlimited users.

-

Intuitive UI and fast learning curve for operations teams.

-

Built-in mobile access and dashboards are a major plus.

⚠️ Challenges:

-

Initial configuration requires strong VAR (partner) guidance.

-

Lacks deep functionality for very large or heavily regulated manufacturers.

-

Some advanced reports may require customization or add-ons.

▪️ What’s the official website for Acumatica Manufacturing?

🔗 Acumatica Manufacturing Edition

-

-

7️⃣ SAP Business One

Global-grade ERP for small to mid-sized manufacturers

▪️ What makes SAP Business One ideal for SMB manufacturers?

SAP Business One (SAP B1) is built specifically for small to medium-sized manufacturers that need international-grade capabilities in a leaner package. Unlike SAP S/4HANA, which targets massive enterprises, SAP B1 gives SMBs access to advanced supply chain, inventory, and production control — without the complexity or cost of large-scale ERP.

It’s widely used by manufacturers who export globally, manage complex BOMs, and need multi-currency and multi-language support built-in.

▪️ What manufacturing features does SAP Business One include?

-

Bill of Materials (multi-level)

-

Work order management and production scheduling

-

MRP with demand forecasting

-

Warehouse management and inventory control

-

Batch and serial number tracking

-

Integrated purchasing and financials

-

Real-time cost tracking and gross margin reports

▪️ What other systems does SAP B1 integrate with?

-

Shop floor systems through add-ons (BoyumIT, Beas Manufacturing)

-

CAD/PLM tools via third-party connectors

-

Shipping/logistics platforms

-

eCommerce (Magento, Shopify)

-

Microsoft Excel, Outlook, and BI tools

-

Seamless SAP-certified integrations for CRM, accounting, and HR

▪️ Which manufacturers are using SAP Business One today?

-

Cosmetics companies like Olivella use SAP B1 to manage production and international sales.

-

Auto parts manufacturers rely on SAP B1 for inventory traceability and quality management.

-

Furniture and lighting manufacturers use SAP B1 to control costs from sourcing through delivery.

▪️ What do real users say about SAP Business One?

🌟 Positives:

-

Great balance between affordability and SAP-grade power.

-

Extensive global support and certified partner network.

-

Solid core features for MRP and international trade.

⚠️ Challenges:

-

The interface is dated compared to newer cloud ERPs.

-

Licensing can be complex due to modular add-ons.

-

Some features rely on third-party extensions (especially for manufacturing depth).

▪️ What’s the official website for SAP Business One?

🔗 SAP Business One for Manufacturing

-

-

8️⃣ SYSPRO

Precision Manufacturing ERP for Highly Regulated Industries

▪️ Why is SYSPRO a standout choice for manufacturers?

SYSPRO is built specifically for manufacturing and distribution businesses, offering a robust, deeply configurable ERP system tailored to complex environments like electronics, industrial equipment, and medical device production. It shines in industries with strict compliance, traceability, and real-time operational control needs, supporting both discrete and batch production across single or multi-site operations.

▪️ What manufacturing features does SYSPRO offer?

-

Advanced BOM and routing for complex product structures

-

Real-time shop floor control with IoT integrations

-

Built-in lot and serial traceability for full regulatory compliance

-

Automated WIP accounting, scrap tracking, and quality control

-

Native support for project-based production, job costing, and subcontracting

-

Strong inventory optimization, forecasting, and procurement workflows

▪️ What integrations are available with SYSPRO?

-

CAD and PLM systems via partner solutions

-

MES, SCADA, and shop floor data collection tools

-

Power BI and third-party analytics dashboards

-

Ecommerce (B2B portals), warehouse systems, and EDI networks

-

Native mobile and web apps for operations, finance, and procurement

▪️ Any real-world case examples using SYSPRO?

-

An aerospace parts manufacturer uses SYSPRO for traceability and strict ISO compliance.

-

A medical device company manages FDA and EU MDR compliance with its full audit trail features.

-

A high-tech electronics firm uses it to control inventory, procurement, and complex multi-level BOMs across global sites.

▪️ What do real manufacturers say about SYSPRO?

🌟 Positives:

-

Purpose-built for manufacturers with strong traceability and compliance support

-

Excellent configurability across modules without custom code

-

Very high marks for stability, uptime, and data reliability

⚠️ Challenges:

-

UI/UX can feel less intuitive compared to cloud-first competitors

-

Steeper learning curve in implementation for small teams

-

Customization may require SYSPRO consultants or partners

▪️ Where can I explore SYSPRO further?

🔗 SYSPRO Manufacturing ERP – Official Overview

-

-

9️⃣ Plex ERP

What type of manufacturers is Plex ERP built for?

Plex ERP is designed specifically for manufacturers in highly regulated, high-throughput industries. Key sectors include:

-

Automotive and aerospace supply chains

-

Industrial equipment and fabricated metals

-

Plastic and rubber molding operations

-

Food and beverage processing with safety requirements

It’s ideal for facilities that demand real-time production visibility, traceability, and native shop-floor control — not just accounting.

What key manufacturing features does Plex ERP deliver?

-

Embedded Manufacturing Execution System (MES) for real-time control

-

BOM-driven production scheduling and material tracking

-

Integrated Quality Management System (QMS)

-

Full traceability for batches, serialized parts, ingredients

-

Detailed equipment and tooling management

-

Real-time dashboards across operations, finance, and inventory

How does Plex handle integrations and deployment?

-

100% cloud-native SaaS architecture for scalable multi-site rollouts

-

REST APIs for MES, SCADA, PLCs, and IoT tool connections

-

Native integrations with logistics, EDI, and analytics platforms

-

Mobile-friendly UI for operators, supervisors, and executives

-

Role-based access to shop-floor and enterprise data in real time

What makes Plex ERP stand out for manufacturing use?

-

Built for plant-floor operations first, unlike generic ERPs

-

Combines ERP + MES in one unified cloud platform

-

Supports strict industry compliance standards like IATF 16949, FSMA, ISO

-

Built-in dashboards for OEE, waste, cycle time, and inventory turns

-

Used by global tier-1 and tier-2 manufacturers to run lean operations

What do real manufacturers say about Plex ERP?

🌟 What users love:

-

Powerful plant-level visibility and audit trails

-

Easy for operators and plant managers to use

-

Strong quality tracking and traceability tools

⚠️ Common pain points:

-

Implementation often requires certified Plex consultants

-

Financial and reporting modules are less flexible than some competitors

-

Some UI components feel outdated without customization

Where can I learn more about Plex ERP?

You can explore the official ERP product page at:

🔗 https://www.plex.com/products/erp

-

-

🔟 Odoo

▪️ What manufacturing industries is Odoo suited for?

Odoo is a highly modular ERP platform popular with small to mid-sized manufacturers across various sectors, including:

-

Discrete manufacturing (electronics, machinery)

-

Process manufacturing (food and beverage, chemicals)

-

Custom and job-shop environments

-

Small batch and mixed-mode production

Its flexibility allows manufacturers to build exactly the workflows they need without overpaying for unused features.

▪️ What key manufacturing features does Odoo provide?

-

Bill of Materials (BOM) with multi-level routing

-

Manufacturing Resource Planning (MRP) with scheduling

-

Quality checks and control points

-

Work order management and tracking

-

Inventory and warehouse management integrated

-

Maintenance management for equipment

-

Real-time production dashboards and reporting

▪️ How does Odoo handle integrations and deployment?

-

Cloud-hosted SaaS or on-premise options

-

Open API for integration with MES, SCADA, and IoT tools

-

Connects easily with Odoo’s CRM, eCommerce, and accounting modules

-

Marketplace apps extend functionality (EDI, logistics, etc.)

-

Mobile-friendly interfaces for shop floor use

▪️ What makes Odoo ERP unique for manufacturers?

-

Fully open-source core with active developer community

-

Highly customizable with no vendor lock-in

-

Cost-effective for SMBs with scalable pricing

-

Modular design allows growth as needs evolve

-

Strong ecosystem of third-party apps and partners

▪️ What do real users say about Odoo ERP?

🌟 Positives:

-

Flexible and customizable to fit specific manufacturing workflows

-

Affordable pricing compared to big-name ERPs

-

Active community support and regular updates

⚠️ Challenges:

-

Steeper learning curve due to modularity

-

Some advanced manufacturing features require third-party add-ons

-

Implementation may need technical expertise or partners

▪️ Where can I explore Odoo ERP further?

🔗 Odoo Manufacturing ERP – Official Product Page

-

-

🔷 YouConclude: Which Is Right for Your Business?

✓ YouConclude

Choosing the right ERP software comes down to one thing: fit. The perfect ERP is not the one with the most features, but the one that aligns with your company size, manufacturing type, growth stage, and digital maturity. Here's how to make a confident, informed decision:

🧮 Best ERP by Company Size

For small and mid-sized businesses (SMBs) with 1 to 100 employees, the top ERP options are Odoo, SAP Business One, and Acumatica. These platforms offer robust functionality with relatively low overhead, and they’re ideal for companies just starting their digital transformation journey.

For mid-market manufacturers with 100 to 500 employees, look to Epicor Kinetic, Infor CloudSuite Industrial, and SYSPRO. These ERPs strike a balance between depth of manufacturing features and usability, offering strong support for growing operations with more complex workflows.

For large enterprises with over 500 employees, consider heavyweights like SAP S/4HANA, Microsoft Dynamics 365, and Oracle NetSuite. These systems are built to scale globally, integrate across departments, and handle high-volume, multi-plant, and multi-currency environments.

🏭 ERP Recommendations by Manufacturing Type

If you're in discrete manufacturing or run a job shop, solutions like Epicor, SYSPRO, and Acumatica are well-suited to your operational style. They offer strong support for work orders, routing, and job costing.

For process manufacturers—such as those in chemicals, pharmaceuticals, or food production—Infor CloudSuite, SAP S/4HANA, and Plex ERP are strong contenders due to their strengths in lot tracking, compliance, and traceability.

If your operations focus on batch production or make-to-order workflows, Oracle NetSuite, Microsoft Dynamics 365, and Epicor Kinetic provide the flexibility and industry-specific functionality you’ll need.

Mixed-mode manufacturers that blend discrete, batch, or MTO processes will benefit from the versatility of platforms like SAP Business One, SYSPRO, or Epicor, which can support multiple production models within one system.

Deployment Speed vs Customization

If speed of deployment is your top priority, opt for cloud-first ERPs like NetSuite, Odoo, or Acumatica. These platforms are modular, quick to implement, and don’t require heavy infrastructure.

If you need deep customization and complex integrations, consider Microsoft Dynamics 365, Epicor Kinetic, or SAP S/4HANA. These offer powerful configuration options but often require longer rollout timelines and more specialized support.

When cost is a critical concern, systems like Odoo, SAP Business One, and Acumatica offer excellent value for money with lower total cost of ownership over time.

If you're looking for strong out-of-the-box manufacturing features with minimal setup, SYSPRO, Infor CloudSuite, and Plex ERP deliver pre-configured templates tailored to specific industries.

General vs Niche ERP: What Should You Choose?

A general-purpose ERP like SAP, Oracle, or Microsoft Dynamics is a smart choice if your organization needs a unified platform across finance, HR, and operations — especially if you have a dedicated IT team capable of managing complex environments.

In contrast, a niche manufacturing ERP like Plex, Epicor, or SYSPRO may be better suited if you want rapid ROI, manufacturing-specific workflows, and personalized vendor support from people who understand your industry.

🎯 Final Recommendations Based on Common Use Cases

If you’re a first-time ERP buyer at a growing small manufacturer, start with Odoo, Acumatica, or SAP Business One. They’re accessible, scalable, and easy to implement.

For high-mix/low-volume job shops, Epicor Kinetic and SYSPRO offer excellent scheduling, costing, and shop floor control capabilities.

If you're in a heavily regulated industry like pharmaceuticals or food, prioritize compliance-focused ERPs like Infor CloudSuite, SAP S/4HANA, or Plex ERP, which offer traceability, lot control, and regulatory reporting features.

Enterprises with multiple global plants and warehouses should look to SAP S/4HANA, Microsoft Dynamics 365, or Oracle NetSuite for their scalability, multi-site management, and integrated business intelligence.

For make-to-order or configure-to-order manufacturers, Acumatica and Microsoft Dynamics 365 deliver the flexibility needed to support variable production and customer-specific configurations.

Start by identifying your core manufacturing needs, then match them with an ERP system that can scale with you — not overwhelm you. Avoid the temptation to chase features you don’t need. Instead, focus on choosing a platform that enhances visibility, efficiency, and control across your operations.

-

✓ YouConclude More

🔄Construction chaos or controlled execution? The ERP you choose decides.

This list breaks down the top construction ERP platforms, covering field tracking, job costing, and contractor workflows — all ranked to help you build smarter.👉 Best Construction ERP Systems: Top 10 Ranked & Reviewed

🔄 Warehouses don’t run on hope — they run on efficiency, and the right ERP makes all the difference.

This guide ranks the top 10 distribution-focused ERP systems that streamline logistics, reduce delays, and optimize inventory in real time.👉 10 Best Distribution ERP Solutions for Supply Chain Efficiency

🔄 Want powerful ERP without the price tag?

Discover the top free ERP platforms that punch above their weight — including open-source options built to scale, streamline operations, and drive real ROI for lean SMBs.

👉 Best Free ERP Software Options (Ranked + Compared)

🔄 Choosing an ERP system shouldn’t feel like guesswork.

This battle-tested framework walks you through the entire ERP selection process — with clear, confident steps to help you avoid costly missteps and choose with precision.

👉 How to Choose an ERP System: Step-by-Step Guide

🔄 Rolling out ERP? One wrong move can stall your business.

Follow this expert-led roadmap to execute your ERP implementation with confidence — from planning and data migration to user training and go-live optimization.

👉 ERP Implementation Guide for SMBs: Step-by-Step Plan

🔄 One ERP launch. Two strategies. Only one is right for your business.

This deep comparison of Big-Bang vs Phased go-lives breaks down the risks, benefits, and technical impact — so you can choose the rollout method that protects uptime and supports growth.

👉 Big-Bang vs Phased ERP Go-Live: Which Is Right for Your SMB?

🔄 Not sure whether to choose Cloud ERP or stick with On-Premise?

You’re not alone. This guide unpacks the core differences in cost, control, scalability, and security — with detailed insights and real-world comparisons built for IT leaders and growth-focused operations teams.👉 Cloud ERP vs On-Premise: Key Differences Explained

🔄 CRM vs ERP: What’s the Difference & Which Do You Really Need?

Confused between CRM and ERP? You’re not alone. This guide breaks down the real differences, use cases, and ROI impact — with deep analysis and real-world examples designed for operational and growth-focused decision-makers.👉 CRM vs ERP: What’s the Difference & Which Do You Really Need?

🔄 ERP vs MRP: Full Breakdown for Business Decision-Makers

Still torn between ERP and MRP? Learn which system will actually drive results for your operations — with deep comparisons, expert insights, and real-world examples made for serious decision-makers.👉 ERP vs MRP: Full Breakdown for Business Decision-Makers

🔄 What Is ERP? A Complete Guide for SMBs (No Fluff)

Learn everything about ERP systems — how they work, core modules, real-world use cases, benefits, costs, and how to choose the right one for your growing business.👉 Master ERP from A to Z — No Need to Read Another Guide

🔄 The 7 Best ERP Systems for Large Enterprises

Expert-vetted list of powerful ERP platforms built to handle global operations, complex workflows, and enterprise-grade integrations at scale.👉 Discover Which ERP System Powers Leading Enterprises

🔄 The 7 Best ERP Tools for Small & Mid-Sized Businesses

Find easy-to-use, scalable, and affordable ERP platforms made for growing SMBs — with features, pricing, and integrations compared in detail.👉 Choose the Right ERP System to Fuel Your Business Growth

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0