ERP vs MRP: Full Breakdown for Business Decision-Makers

ERP vs MRP: What’s the difference? Learn how each system works and which one fits your business best — and make the right decision.

Table of Contents

- 1️⃣ What Is ERP?

- 2️⃣ What Is MRP?

- 3️⃣ ERP vs MRP: What’s the Core Difference?

- 4️⃣ Which System Do You Need: ERP or MRP?

- 5️⃣ Key Features: ERP vs MRP Modules Compared

- 6️⃣ Cost Comparison: ERP vs MRP Pricing Explained

- 7️⃣ Common Use Cases and Examples

- 8️⃣ Can ERP Replace MRP? Or Should They Work Together?

- 9️⃣ How to Choose Between ERP and MRP the Right Way

- 🔷 YouConclude : Which One Wins for Your Business?

- ✓ YouConclude More

-

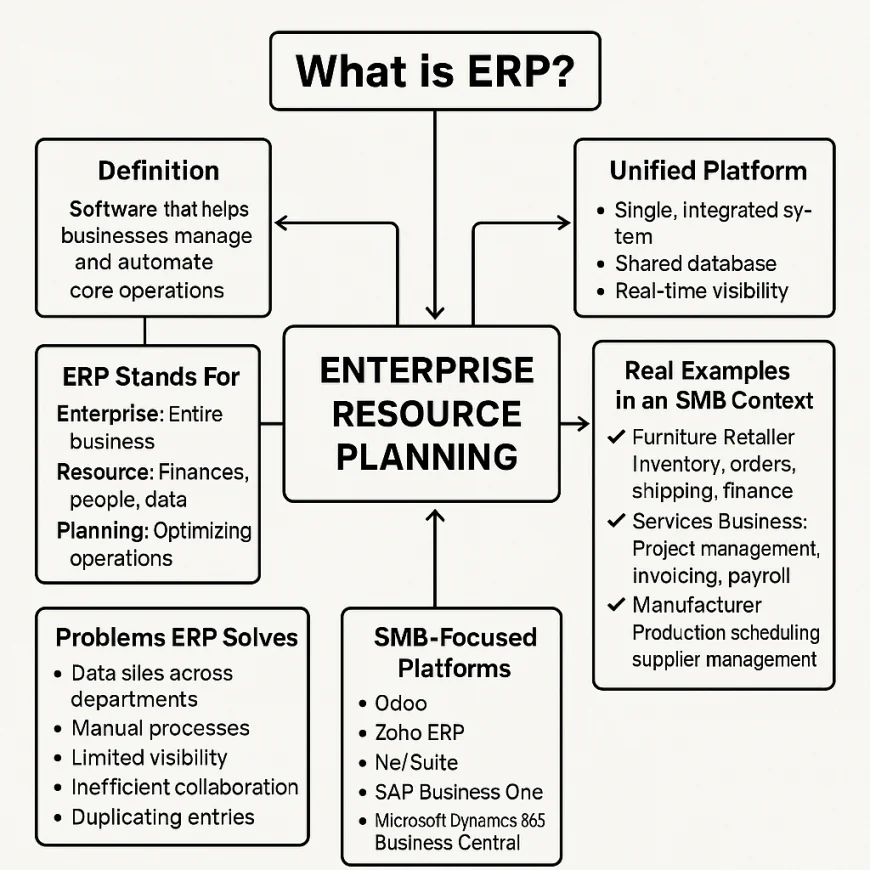

1️⃣ What Is ERP?

Enterprise Resource Planning, Simplified for SMBs

Enterprise Resource Planning (ERP) is a type of software system that centralizes and streamlines a company’s core operations—typically across finance, inventory, HR, procurement, and customer management. Think of it as the digital backbone of a business, connecting departments and data into a single source of truth.

Instead of managing every function in its own siloed tool—like spreadsheets for accounting, another app for inventory, and a separate CRM—an ERP integrates all of these into one unified platform. This integration improves accuracy, speed, and visibility across the organization.

Real-World ERP Example

Let’s say you run a mid-sized wholesale company. An ERP system would allow:

-

Sales to see live inventory before promising delivery.

-

Finance to auto-update revenue when invoices are generated.

-

Procurement to trigger restocking based on sales velocity.

-

Executives to view real-time dashboards on performance.

All these actions stem from one centralized system, removing the need for manual reconciliation and improving overall decision-making.

What ERP Is Not

ERP is often confused with:

-

Accounting software like QuickBooks — which only handles finances.

-

MRP systems — which focus primarily on manufacturing materials and scheduling.

-

Point solutions like CRMs or HR tools — which don’t offer unified visibility across business operations.

An ERP, by contrast, acts as a comprehensive operating system for your business.

Why It Matters for SMBs

ERP isn’t just for enterprises anymore. Cloud-based ERP solutions like NetSuite, Zoho ERP, or Odoo are now affordable, modular, and scalable — giving small businesses enterprise-grade power without massive upfront investment.

It allows smaller teams to do more with fewer people by automating manual processes, eliminating double data entry, and surfacing actionable insights in real time.

-

-

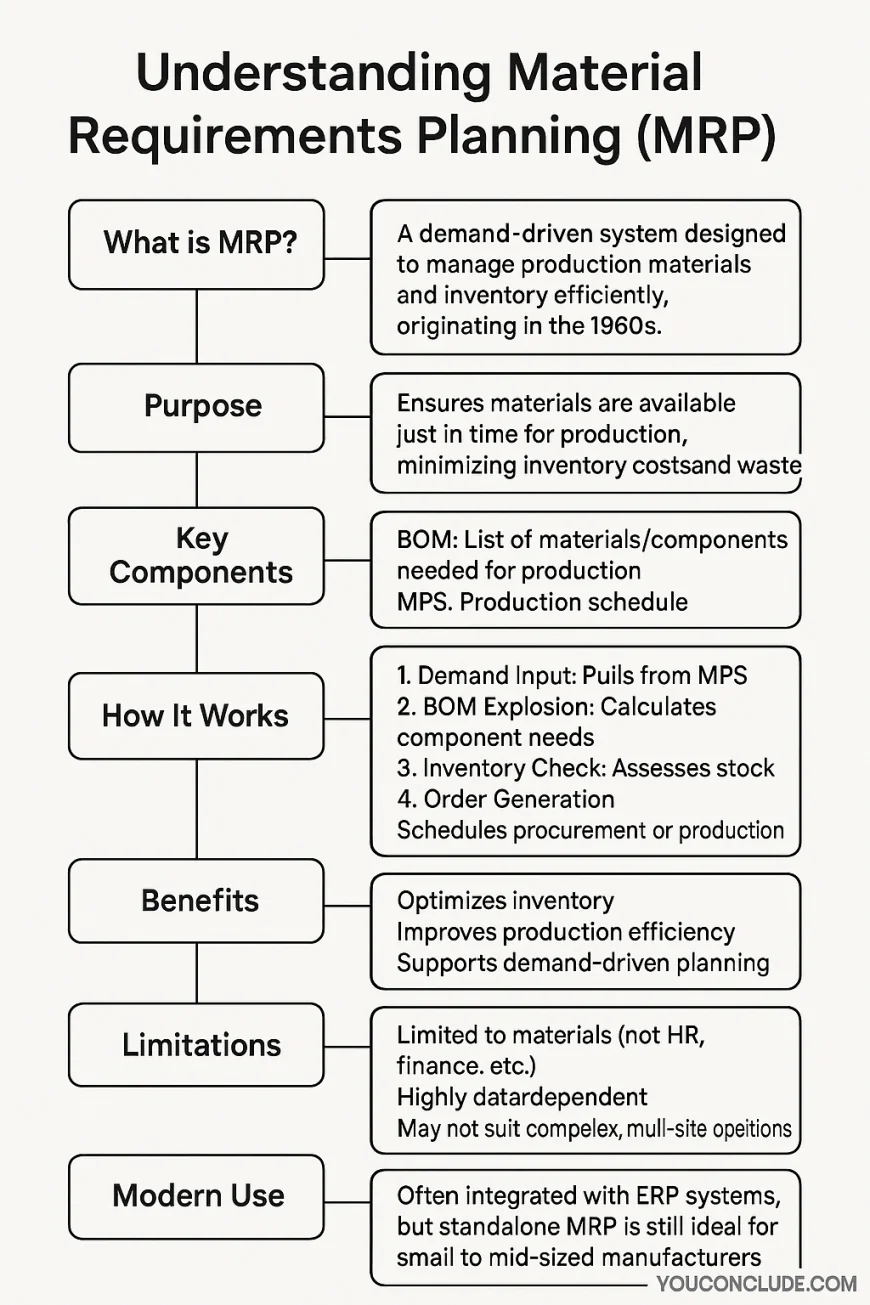

2️⃣ What Is MRP?

Defining Material Requirements Planning (MRP)

Material Requirements Planning (MRP) is a manufacturing-focused, demand-driven system designed to efficiently manage production materials and inventory. Originating in the 1960s, MRP revolutionized factory operations by automating the calculation of raw material needs based on production schedules and sales forecasts.

Unlike broader enterprise systems, MRP’s primary goal is to ensure materials are available precisely when needed to meet production demands while minimizing inventory carrying costs and reducing waste. It acts as the backbone of supply chain planning in manufacturing environments.

Core Components of MRP

-

Bill of Materials (BOM): The hierarchical list of raw materials, components, and subassemblies required for product manufacturing. BOM is fundamental for accurate material planning.

-

Inventory Records: Real-time data about current stock levels, lead times, and safety stock thresholds.

-

Master Production Schedule (MPS): A timetable detailing what finished goods are to be produced and when. MRP uses this to forecast raw material requirements backward.

How MRP Works: Process Flow

-

Demand Input: MRP receives production requirements from the MPS, representing finished goods demand.

-

Explosion of BOM: It "explodes" the BOM to determine quantities of each component or raw material required per finished product.

-

Inventory Check: MRP cross-references current inventory and open purchase orders to calculate net requirements.

-

Order Generation: Based on lead times and order policies, MRP schedules purchase orders or manufacturing orders to replenish materials just in time for production.

Benefits of MRP

-

Inventory Optimization: Prevents overstocking and stockouts, freeing up working capital.

-

Improved Production Efficiency: Ensures materials arrive exactly when needed, reducing downtime.

-

Demand-Driven Planning: Reacts to customer orders and sales forecasts for flexible production.

Limitations and Challenges

-

Scope Restriction: MRP focuses exclusively on material planning — it does not manage finance, HR, CRM, or other business functions, limiting its use in broader operational contexts.

-

Data Dependence: Accuracy hinges on reliable BOMs, inventory records, and forecasts. Poor data quality can cause costly errors.

-

Not Ideal for Complex Operations: Manufacturers with intricate supply chains, multiple sites, or non-standard production processes may outgrow basic MRP.

MRP in the Modern Business Environment

While MRP began as standalone software, it is now often integrated as a module within full ERP systems to provide seamless end-to-end operational control. Yet, standalone MRP remains valuable for small to mid-sized manufacturers with focused production needs who want cost-effective, targeted material planning without the complexity of full ERP suites.

-

-

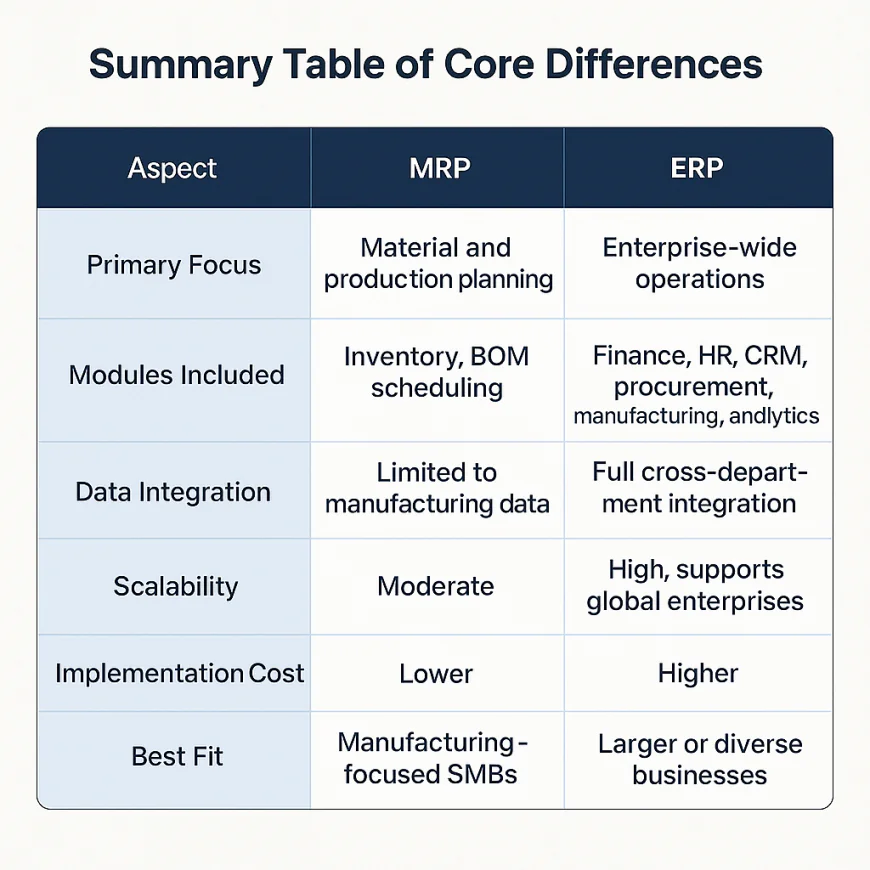

3️⃣ ERP vs MRP: What’s the Core Difference?

Understanding the Fundamental Differences Between ERP and MRP

At their core, ERP (Enterprise Resource Planning) and MRP (Material Requirements Planning) serve different but sometimes overlapping purposes in business operations. Recognizing these foundational differences is key to making the right software investment.

Scope and Functionality

-

MRP: Focused Material Planning System

MRP is primarily designed to manage materials, inventory, and production scheduling within manufacturing. Its function is to ensure raw materials and components are available for timely production runs, helping to optimize inventory levels and reduce stockouts or overstock. MRP systems typically do not handle non-manufacturing business processes. -

ERP: Integrated Business Management System

ERP extends beyond manufacturing and inventory management to encompass end-to-end business operations across departments. It integrates modules for finance, human resources, customer relationship management (CRM), procurement, supply chain, sales, and more — providing a single unified database and interface.

Architecture and Data Flow

-

MRP Architecture

MRP operates with a centralized database focused on production data, BOMs, and inventory records. It “explodes” production requirements into raw material demands but typically lacks cross-departmental data integration. -

ERP Architecture

ERP systems use a centralized and modular architecture that connects all business functions into one platform. This integrated data flow enables real-time visibility across finance, manufacturing, sales, and HR, allowing for coordinated decision-making at the enterprise level.

Workflow Differences

-

MRP Workflows

Focused on the production cycle, MRP workflows are built around planning raw material procurement and manufacturing schedules, using data inputs like sales forecasts and BOMs. The output primarily drives purchase orders and production orders. -

ERP Workflows

ERP workflows support broader business processes, such as order-to-cash, procure-to-pay, financial closing, and workforce management. ERP enables automating and streamlining these processes holistically rather than in isolated silos.

Use Case Suitability

-

MRP is best for:

-

Small to mid-sized manufacturers with straightforward production needs

-

Businesses that primarily need material planning without complex operational demands

-

Companies aiming for cost-effective, focused inventory control

-

-

ERP is best for:

-

Medium to large businesses requiring integrated management of multiple departments

-

Organizations seeking real-time data analytics and cross-functional collaboration

-

Companies that want scalable platforms supporting growth beyond manufacturing

-

Why This Matters for Business Decision-Makers

Choosing between ERP and MRP depends on your company’s operational complexity, growth ambitions, and functional requirements. Selecting MRP might save costs initially but risks process fragmentation as your business grows. Conversely, ERP offers a comprehensive solution but requires greater investment and organizational readiness.

-

-

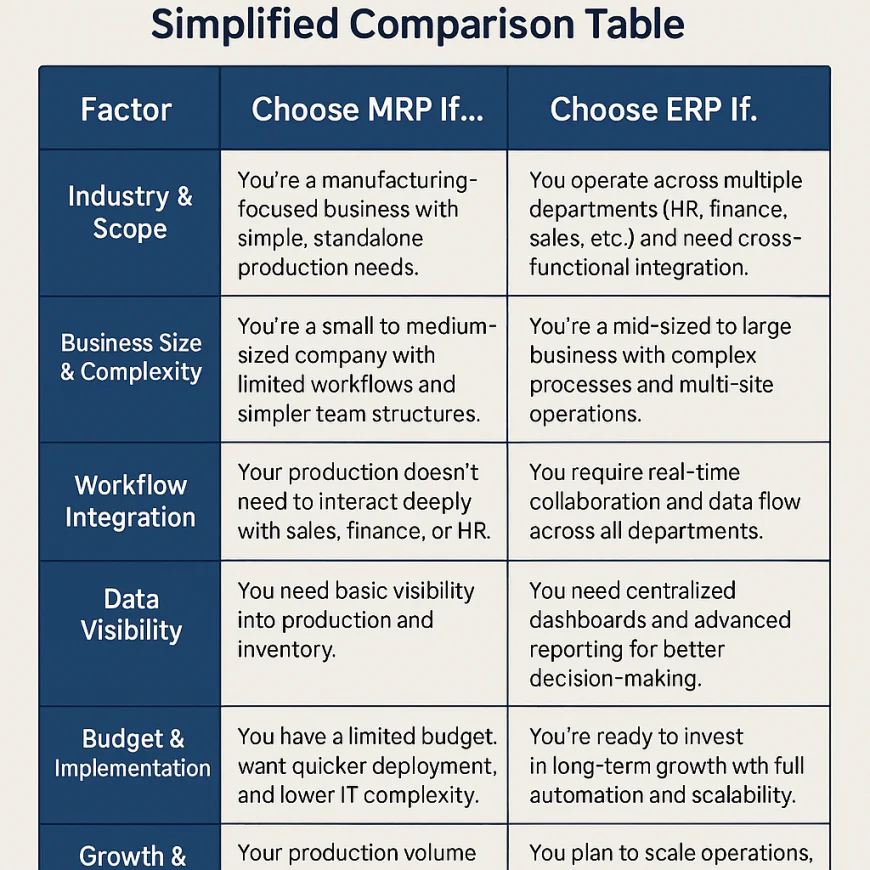

4️⃣ Which System Do You Need: ERP or MRP?

Choosing between ERP and MRP depends on your business’s unique operational demands, growth ambitions, and industry focus. This decision is crucial as the wrong choice can lead to wasted investment or missed efficiencies.

Industry and Operational Scope

If your business is primarily manufacturing-focused with relatively straightforward production processes, an MRP system is often sufficient. MRP excels at handling material requirements, production scheduling, and inventory control. It is especially suited for companies that do not require extensive integration beyond manufacturing operations.

However, if your business involves multiple departments such as finance, sales, human resources, customer support, and supply chain management, an ERP system is better suited. ERP integrates these functions into a single platform, enabling seamless data flow and eliminating silos, which improves overall operational transparency.

Business Size and Complexity

Small to medium-sized businesses with simple manufacturing workflows and limited departmental interdependencies typically find MRP systems easier to implement and more cost-effective. These systems demand less training and fewer IT resources, making them ideal for organizations with smaller teams or startups.

On the other hand, medium to large enterprises with complex workflows, multiple locations, or diverse operational needs benefit from ERP solutions. ERP systems support more users, advanced permission controls, and cross-functional processes that streamline collaboration and decision-making.

Workflow Integration and Data Visibility

If your manufacturing process is relatively standalone, where production planning and material procurement do not need to directly interact with other departments, MRP’s focused capabilities will suffice. But when your operations demand real-time data sharing between departments—such as syncing production with sales forecasting, finance, and procurement—an ERP system’s integrated architecture provides a critical advantage.

ERP systems enhance visibility by providing centralized dashboards and reporting tools that empower leaders to make data-driven decisions quickly. MRP systems, while excellent for production control, usually offer limited insights into the broader business performance.

Budget Considerations and Implementation Readiness

MRP solutions generally come with a lower total cost of ownership. They require less upfront capital, fewer resources to implement, and can be deployed more quickly. This makes them attractive for businesses with tight budgets or limited IT infrastructure.

Conversely, ERP implementations involve significant investment—both financially and in terms of organizational change management. But this investment pays off by automating complex business processes, reducing manual errors, and scaling operations efficiently as the company grows.

Growth and Future-Proofing

If your business anticipates steady growth and plans to expand beyond manufacturing into new markets, channels, or product lines, ERP systems provide scalability and flexibility. They allow adding new modules or users without disrupting core operations.

For businesses expecting stable production volumes without immediate plans for diversification, MRP remains a cost-effective, focused choice.

Summary:

-

Choose MRP if your focus is on streamlined manufacturing operations with straightforward workflows, smaller teams, and limited budgets.

-

Choose ERP if your business requires cross-departmental integration, scalability, enhanced data visibility, and a system that supports complex, growing operations.

-

-

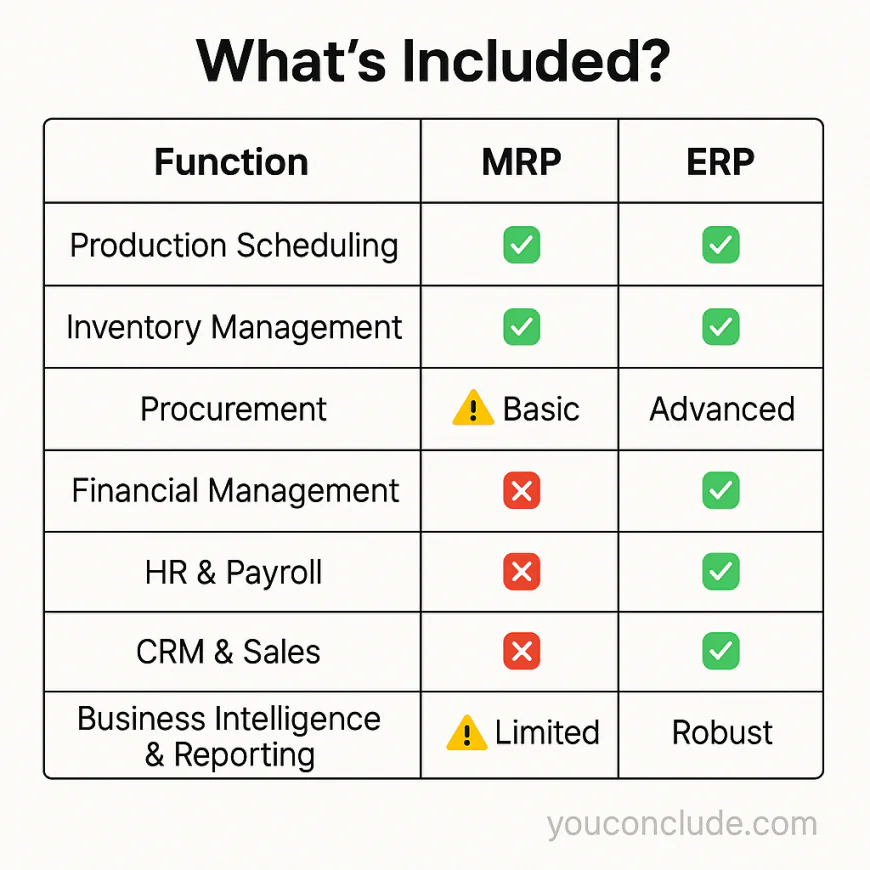

5️⃣ Key Features: ERP vs MRP Modules Compared

Understanding the core features of ERP and MRP systems is essential for selecting the right solution. While both systems aim to streamline business operations, their scope, modular design, and integration capabilities differ significantly.

✅ Core Focus Areas

MRP systems are purpose-built for manufacturing. Their key strength lies in managing production schedules, ensuring material availability, and optimizing inventory levels. The three foundational elements of MRP are:

-

Bill of Materials (BOM) processing

-

Inventory control

-

Production planning and scheduling

By contrast, ERP systems offer a broader scope. ERP platforms integrate all business functions across departments — from manufacturing to HR, finance, procurement, CRM, and beyond. This makes ERP ideal for organizations looking for full business process automation and centralized data visibility.

🔧 Production Planning & Scheduling

MRP’s scheduling tools focus on when and how much to produce based on material availability and customer demand. It automatically triggers reorder points, aligns raw materials with production deadlines, and minimizes stockouts or overproduction.

ERP also includes production scheduling, but within a broader context. For example, ERP can account for project budgets, staffing constraints, customer deadlines, and procurement lead times — all in a single planning module.

📦 Inventory & Procurement

MRP tracks raw materials and finished goods, issuing purchase orders when inventory hits a minimum threshold. It’s effective in just-in-time (JIT) environments where excess inventory is costly.

ERP takes inventory a step further. It integrates procurement with sales forecasting, finance, and vendor management. It can help prioritize purchases based on cash flow, vendor reliability, or strategic sourcing — which MRP alone cannot do.

🧾 Financial Management

MRP systems typically do not include financial tools. Any financial analysis must be done manually or using separate software.

ERP platforms include robust financial modules:

-

Accounts payable & receivable

-

General ledger

-

Bank reconciliation

-

Multi-currency support

-

Budgeting and forecasting

This integration enables real-time cash flow analysis, financial reporting, and compliance tracking.

👥 HR & Workforce Management

Another key ERP advantage is its human resource functionality. ERP systems often include:

-

Employee onboarding

-

Payroll

-

Shift scheduling

-

Time tracking

-

Performance management

MRP systems do not address HR needs and would require separate integrations if such capabilities are needed.

🧩 CRM and Sales Integration

ERP systems often feature built-in Customer Relationship Management (CRM) modules, enabling alignment between sales, service, and delivery. This helps sales teams forecast demand more accurately and communicate with production teams in real time.

MRP systems, however, typically have no CRM capabilities — they assume demand data comes from external systems or manual input.

🔵ERP is a complete business solution — suitable for organizations that need to integrate multiple departments under one system.

🔵 MRP is a focused manufacturing solution — best for managing inventory, raw materials, and production workflows.

-

-

6️⃣ Cost Comparison: ERP vs MRP Pricing Explained

Choosing between ERP and MRP isn’t just about features — it’s also a financial decision. Pricing models, total cost of ownership (TCO), and hidden expenses vary significantly between the two. Here's a breakdown to help you understand what you’ll actually pay.

💰 Licensing Models: Subscription vs Perpetual

MRP software tends to follow simpler pricing structures, especially for small manufacturers. Many use a perpetual license model — you pay once and own the software forever (though support and updates often cost extra). Some cloud-based MRP tools now offer monthly subscriptions, usually ranging from $49 to $200 per user/month.

ERP systems, on the other hand, are typically SaaS-based, billed as monthly or annual subscriptions. Pricing depends on:

-

Number of users

-

Modules included

-

Deployment model (cloud, hybrid, on-premise)

Expect costs in the range of $75 to $300+ per user/month, with enterprise solutions climbing even higher.

🛠️ Implementation & Setup Costs

MRP systems are usually faster to deploy — with focused functionality and fewer integration requirements, some can be set up in days or weeks. Implementation costs range from $1,000 to $15,000, depending on customization and training.

ERP systems involve extensive configuration. Implementation for even mid-sized businesses often includes:

-

Business process mapping

-

Data migration

-

Role permissions setup

-

Integration with accounting, CRM, payroll, etc.

Costs can reach $30,000 to $250,000+, especially for enterprise-grade systems like NetSuite or SAP.

🎓 Training and Change Management

ERP rollouts almost always require employee training across departments, and in some cases, dedicated change management teams.

-

Training costs: $2,000 to $20,000, depending on company size

-

Time to adoption: 2–6 months, or more for complex orgs

MRP training is narrower — usually focused on the production or procurement teams — and far less resource-intensive.

🔄 Ongoing Support & Maintenance

-

MRP: Annual maintenance fees for perpetual licenses average 15–20% of license cost.

-

ERP: Subscription models usually include support. However, additional services like 24/7 phone support or dedicated account managers may cost extra.

On-premise ERP also requires in-house IT support, software patches, and potential downtime mitigation — which add to long-term TCO.

📈 Scalability and Upgrade Costs

MRP tools can become limiting as your company grows. If your team expands beyond manufacturing (e.g., finance, HR, field sales), you may hit a wall and need to upgrade to a more comprehensive ERP.

ERP systems scale much more easily. But that scalability comes at a price — often requiring additional user licenses, storage costs, and add-on modules.

Bottom Line: What’s the Real Cost?

-

✅ MRP is affordable upfront, especially for manufacturers with focused needs

-

✅ ERP is a bigger investment, but pays off when multiple departments need full integration and centralized data

-

⚠️ Hidden costs (implementation, training, downtime) must be factored into both options — not just the subscription price

🧠 Decision Tip: If you're a growing business needing cross-functional visibility, consider ERP early — retrofitting MRP tools with bolt-on software often costs more in the long run.

-

-

7️⃣ Common Use Cases and Examples

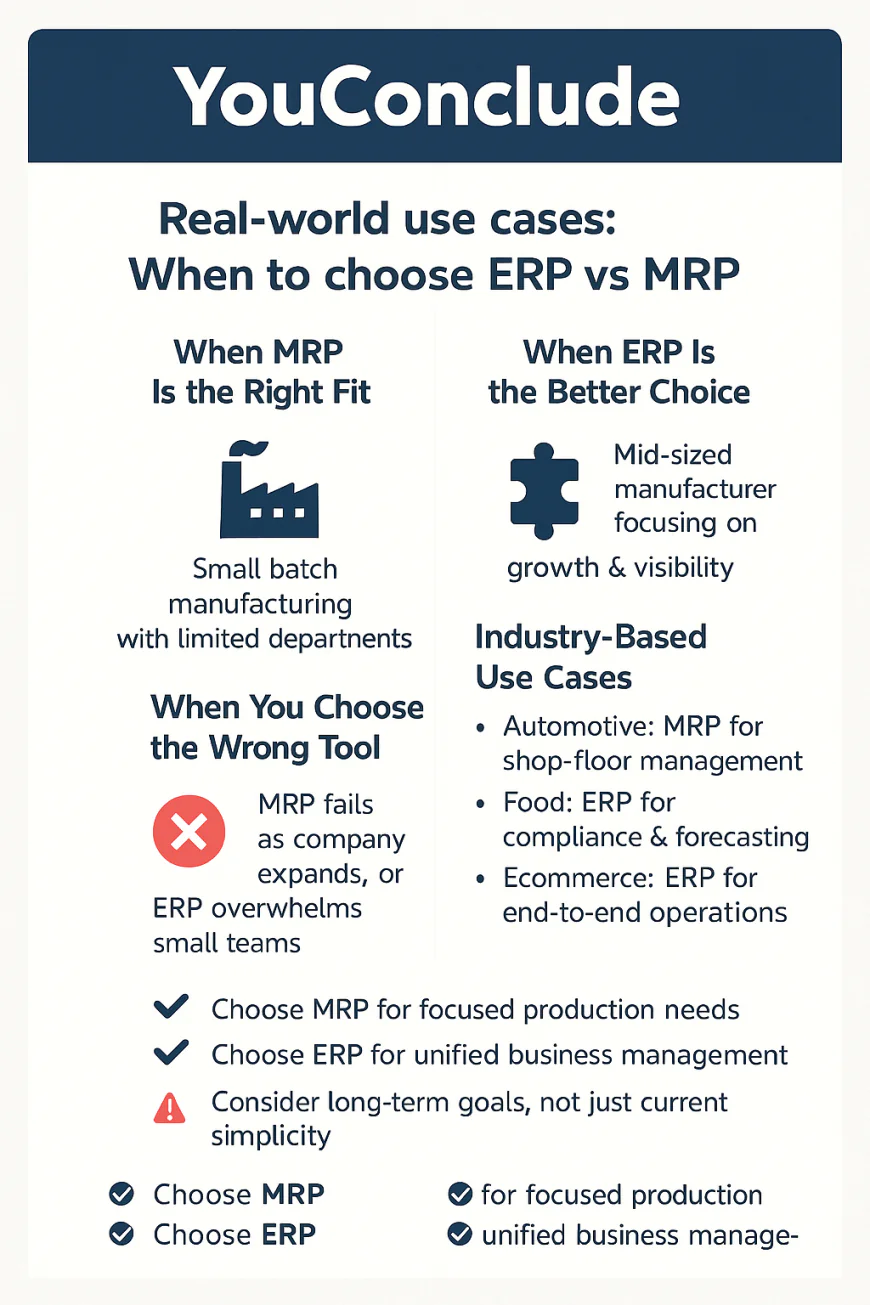

Not sure whether you need ERP or MRP? Let’s look at real-world use cases that show exactly when each system makes sense — and what happens when you choose the wrong one.

🏭 When MRP Is the Right Fit

Use Case 1: A Small Batch Manufacturing Company

Business type: A 20-person operation that manufactures custom parts for industrial clients.

Challenge: Tracking raw materials, managing inventory, and generating work orders efficiently.

Solution: An MRP system like Katana or MRPeasy provides just what they need — without unnecessary features like HR or CRM modules.

Why it works:-

Simple BOM management

-

Inventory sync with production timelines

-

Fast setup, low cost

✅ Perfect for SMBs with under 50 employees, limited departments, and focused production needs.

🧩 When ERP Is the Better Choice

Use Case 2: A Mid-Sized Manufacturer Scaling Operations

Business type: A 100-employee company producing consumer electronics with growing distribution needs.

Challenge: Production was streamlined, but they lacked visibility across finance, sales, inventory, and support.

Solution: Migrated to ERP (like NetSuite or Acumatica) to unify operations across all departments.

Why it works:-

CRM integration for sales reps

-

Financial planning alongside MRP functions

-

Supplier portals and automated invoicing

✅ Ideal for companies expanding into multi-department coordination and need a single source of truth.

🛑 What Happens When You Choose the Wrong Tool?

Scenario: An MRP system in a growing multi-department company

At first, it worked. But as the marketing, finance, and HR teams grew, workarounds began piling up — spreadsheets, disconnected systems, and rekeyed data. Eventually, they had to migrate to ERP… at double the original cost.Scenario: A small shop overcommitting to ERP

A 10-person company implemented a cloud ERP system, but used only 15% of its capabilities. Training took 4 months. Employees were overwhelmed. They eventually downscaled to an MRP tool better suited to their actual workflows.

🔍 Industry-Based Use Cases

-

Automotive Manufacturing: MRP for shop-floor scheduling, ERP for supply chain and global distribution.

-

Food Production: ERP shines in regulated industries — integrated compliance, traceability, and forecasting.

-

Ecommerce-Driven Manufacturing: ERP connects online orders with production, shipping, and accounting.

Summary:

-

✅ Choose MRP if your operations are focused purely on production, inventory, and procurement.

-

✅ Choose ERP if you want unified control over your entire business — from HR to financials to customer support.

-

⚠️ Don't let short-term simplicity lead to long-term fragmentation. Choose based on where your business is headed, not just where it is now.

-

-

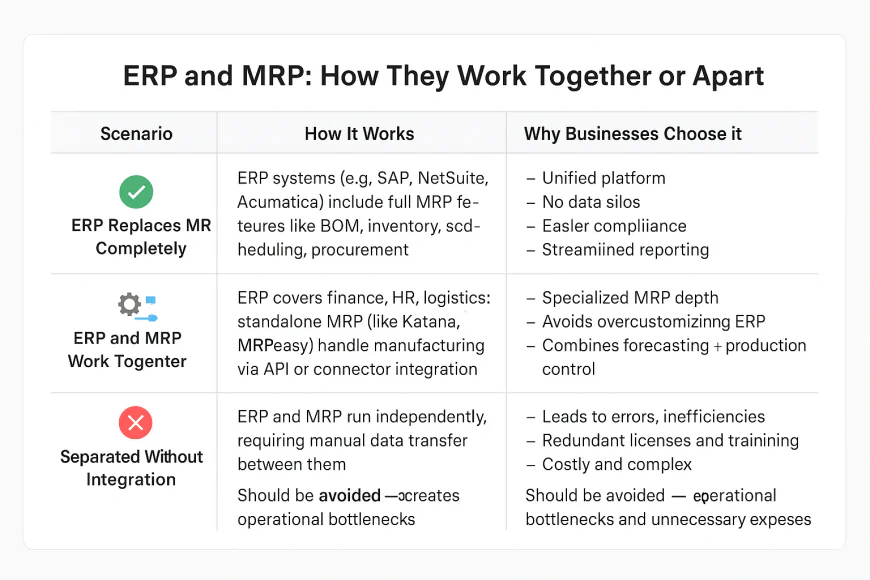

8️⃣ Can ERP Replace MRP? Or Should They Work Together?

The answer depends on your business structure. ERP and MRP are not always in competition — in many cases, they complement each other. Here's how to make the distinction:

✅ When ERP Replaces MRP Completely

Modern ERP systems often include MRP as a module — making it unnecessary to buy separate software.

Example:

Platforms like SAP Business One, Oracle NetSuite, and Acumatica offer integrated manufacturing modules. These include:-

Bill of Materials (BOM) management

-

Inventory and warehouse control

-

Shop-floor scheduling

-

Procurement and vendor coordination

Why this works:

-

One system, one database

-

Unified user experience

-

Easier compliance and reporting

-

Eliminates data silos between production and finance

🔍 Best for: Medium to large businesses that need full visibility across operations, including production.

⚙️ When ERP and MRP Work Together

In some cases, especially for specialized manufacturers, a dedicated MRP system might still outperform the built-in MRP features of generic ERP platforms.

How it works:

-

ERP handles finance, HR, sales, logistics

-

MRP (like Katana, JobBOSS², or MRPeasy) integrates via API for production control

-

Data flows between systems via middleware or native connectors

Why businesses choose this hybrid model:

-

Deep manufacturing capabilities from standalone MRP

-

Business-wide control and forecasting via ERP

-

Avoids overcustomizing ERP for niche production needs

🔍 Best for: SMBs in highly technical or custom production sectors — especially where manufacturing is complex but the rest of the business is relatively lean.

❌ When It’s a Mistake to Separate Them

-

Disconnected systems = operational bottlenecks

If your teams constantly move data between ERP and MRP manually, you're inviting errors and inefficiencies. -

Redundant licenses and training

Running two systems when one modern ERP would do adds cost and complexity.

-

-

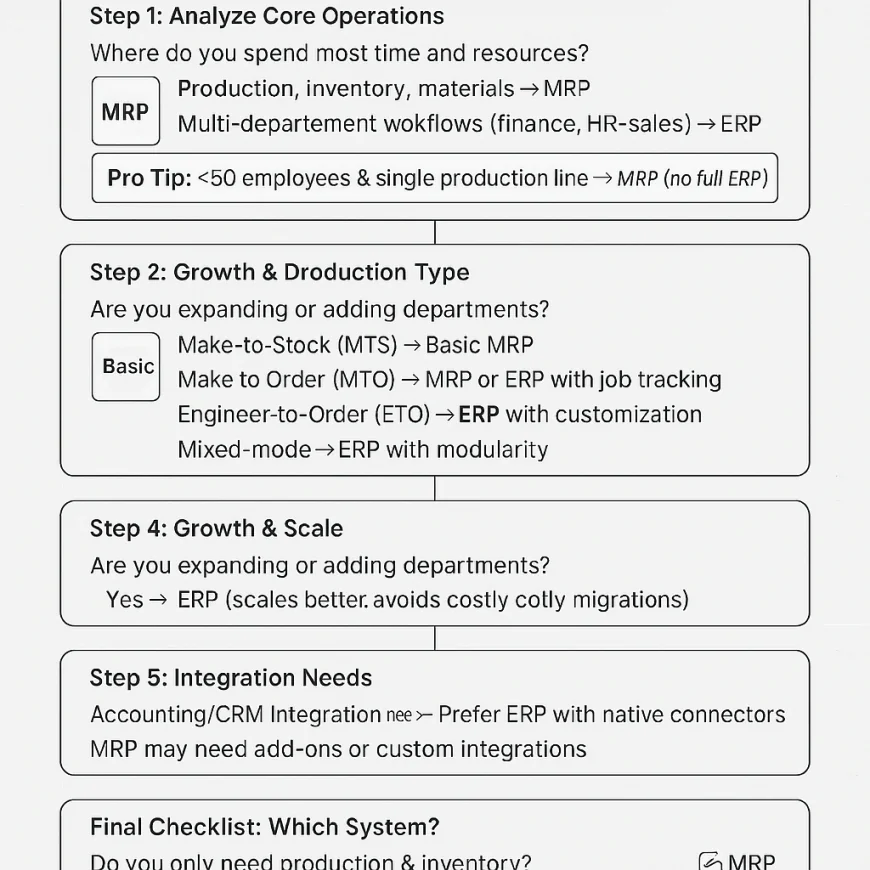

9️⃣ How to Choose Between ERP and MRP the Right Way

Choosing between ERP and MRP is more than a feature comparison — it’s a strategic decision based on your operations, business model, production style, and growth plans. Here’s a practical step-by-step guide designed for decision-makers:

🧩 Step 1: Analyze Your Operational Focus

Start by asking yourself: Where does your business invest the most energy day to day?

-

If your team spends most of its time managing raw materials, inventory levels, and production schedules, an MRP system may be the right starting point.

-

If you also need tools to manage accounting, HR, sales, customer relationships, and procurement, then you’re clearly operating beyond MRP — and should consider an ERP system.

For example, a 20-person manufacturing company focused entirely on production output likely needs only an MRP system. But if the same company also has a dedicated sales and finance team, they’ll outgrow MRP fast.

📦 Step 2: Match System Type to Your Production Style

Your type of manufacturing workflow plays a major role in system fit:

-

Make-to-Stock (MTS): Basic MRP systems are usually sufficient here since forecasting and inventory control are central.

-

Make-to-Order (MTO): You’ll need MRP capabilities plus some job tracking or integration with sales systems. An ERP with MRP functionality may be ideal.

-

Engineer-to-Order (ETO): This requires complex coordination between engineering, procurement, production, and billing — a strong case for full ERP.

-

Mixed-mode manufacturing: If you manage a mix of standard and custom workflows, you’ll benefit from an ERP system that supports modular flexibility.

The more custom and complex your workflows are, the more likely it is that ERP will serve you better.

🌱 Step 3: Assess Your Growth and Scalability Needs

Ask yourself:

-

Are you planning to expand into multiple facilities or regions?

-

Will you be adding teams for HR, customer service, or procurement?

-

Do you want centralized reporting and control across departments?

If the answer to any of these is yes, an ERP system will future-proof your operations. Even if it feels like “too much” right now, it prevents costly migrations or tool switching later on.

🔗 Step 4: Evaluate Your Integration Requirements

Consider the tools you already use. Do you rely on:

-

QuickBooks or Xero for accounting?

-

Salesforce or HubSpot for CRM?

-

Shopify or another ecommerce platform?

If so, you need a system that plays nicely with them. Many ERP platforms offer native or built-in integrations, while MRP tools may require manual workarounds or add-ons.

Look for platforms with open APIs or robust app marketplaces if integration is a top priority.

🧮 Step 5: Don’t Judge by License Price Alone — Budget for the Full Picture

When comparing ERP and MRP systems, don’t stop at the subscription or license cost. Total cost of ownership includes:

-

Initial implementation and data migration

-

Customization and configuration

-

Training and onboarding

-

Ongoing maintenance and support

-

Integration costs with other tools

-

Downtime or transition time from existing systems

Generally, MRP systems are more affordable at first — but they may lack critical business functions, requiring bolt-ons or future upgrades. ERP systems demand more upfront but often eliminate the need for multiple disconnected tools, saving costs and complexity in the long run.

🎯 Final Self-Check Summary: ERP or MRP?

Here’s a quick yes/no self-diagnosis to guide your choice:

-

If your needs revolve strictly around inventory management, production scheduling, and materials procurement → MRP is likely enough.

-

If your business also includes finance, HR, CRM, or multi-department operations → ERP is the better fit.

-

If you’re planning to grow fast, open new locations, or scale your team → Choose ERP for long-term flexibility.

-

If you do custom manufacturing or have complex engineering needs → ERP with integrated MRP capabilities is essential.

-

If you want everything managed on one unified platform → ERP offers the centralization you need.

-

-

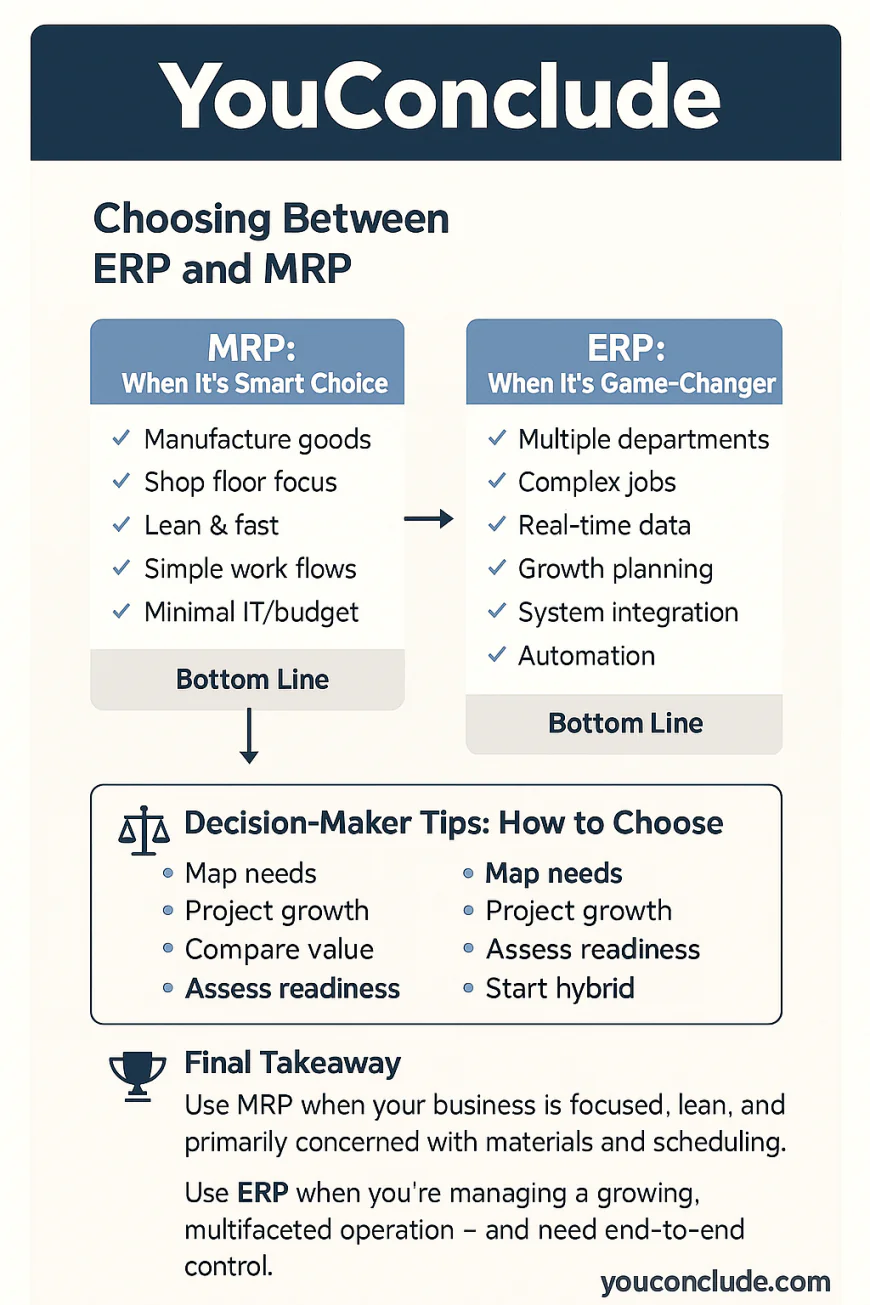

🔷 YouConclude : Which One Wins for Your Business?

✓ YouConclude

Choosing between MRP and ERP is not about one being universally better than the other — it’s about which system aligns perfectly with your business complexity, industry requirements, and growth ambitions. This final verdict distills everything you’ve learned into actionable guidance.

When MRP Is the Smart Choice

MRP shines in companies that:

-

Are focused primarily on manufacturing processes, especially discrete or repetitive production.

-

Have a narrow operational scope: primarily materials planning, procurement, and inventory control.

-

Operate with limited departmental complexity (e.g., no or minimal HR, sales, or finance departments).

-

Prefer a lighter, faster-to-deploy system with a lower upfront cost and less training overhead.

-

Have stable, predictable production workflows like Make-to-Stock or Assemble-to-Order.

-

Require a budget-conscious solution that solves immediate manufacturing pains without unnecessary bells and whistles.

Bottom line: If your business is a small-to-mid-sized manufacturer with well-defined production requirements and limited expansion plans, MRP will give you laser focus, cost efficiency, and rapid ROI.

When ERP Is the Game-Changer

ERP is the go-to system for organizations that:

-

Operate in multiple functional areas beyond manufacturing — finance, HR, sales, CRM, procurement — and need centralized control.

-

Manage complex or mixed-mode production workflows including Engineer-to-Order or Make-to-Order.

-

Require enterprise-wide data visibility for strategic decision-making, forecasting, and compliance.

-

Are planning growth into new markets, multiple locations, or adding product lines requiring flexible, scalable infrastructure.

-

Demand deep integrations with existing software ecosystems like CRM, ecommerce, or accounting platforms.

-

Prioritize workflow automation, real-time analytics, and robust reporting across departments.

-

Value long-term total cost of ownership savings through consolidated systems and streamlined maintenance.

Bottom line: If you’re aiming to build a digitally integrated, scalable operation that connects all facets of your business, ERP is the strategic foundation you need.

⚖️ Strategic Recommendations for Decision-Makers

-

Define your business scope clearly. Map out which departments and processes need system support today and in the future.

-

Evaluate your growth trajectory. Fast-growing businesses should lean towards ERP even if it seems complex initially.

-

Weigh initial costs against long-term benefits. Don’t fall into the trap of chasing the cheapest option if it means more systems and integrations later.

-

Factor in your team’s tech readiness. ERP implementations can require stronger change management and training.

-

Consider hybrid approaches. Some companies implement MRP first, then gradually adopt ERP as they grow or merge.

-

Engage vendors early. Request demos tailored to your workflows and ask about integration capabilities and upgrade paths.

📈 Real-World Example: Manufacturing SMBs in Transition

Take a mid-sized manufacturer producing custom components. Initially, they used an MRP system to manage procurement and production. But as their sales, HR, and financial teams grew, their disconnected systems caused delays, errors, and poor visibility.

They upgraded to an ERP system with integrated MRP functionality, automating workflows from order entry through production and invoicing. This improved cross-team collaboration, reduced manual errors, and gave leadership real-time KPIs to manage growth.

🏆 Final Takeaway

-

For focused manufacturing operations with tight budgets, MRP delivers targeted, cost-effective solutions.

-

For diverse, growing businesses requiring integrated operations and scalability, ERP provides the comprehensive platform essential for long-term success.

Your choice should always be based on a clear-eyed assessment of operational complexity, growth plans, and total cost implications.

-

-

✓ YouConclude More

🔄Construction chaos or controlled execution? The ERP you choose decides.

This list breaks down the top construction ERP platforms, covering field tracking, job costing, and contractor workflows — all ranked to help you build smarter.👉 Best Construction ERP Systems: Top 10 Ranked & Reviewed

🔄 Warehouses don’t run on hope — they run on efficiency, and the right ERP makes all the difference.

This guide ranks the top 10 distribution-focused ERP systems that streamline logistics, reduce delays, and optimize inventory in real time.👉 10 Best Distribution ERP Solutions for Supply Chain Efficiency

🔄 Want powerful ERP without the price tag?

Discover the top free ERP platforms that punch above their weight — including open-source options built to scale, streamline operations, and drive real ROI for lean SMBs.

👉 Best Free ERP Software Options (Ranked + Compared)

🔄 Choosing an ERP system shouldn’t feel like guesswork.

This battle-tested framework walks you through the entire ERP selection process — with clear, confident steps to help you avoid costly missteps and choose with precision.

👉 How to Choose an ERP System: Step-by-Step Guide

🔄 Rolling out ERP? One wrong move can stall your business.

Follow this expert-led roadmap to execute your ERP implementation with confidence — from planning and data migration to user training and go-live optimization.

👉 ERP Implementation Guide for SMBs: Step-by-Step Plan

🔄 One ERP launch. Two strategies. Only one is right for your business.

This deep comparison of Big-Bang vs Phased go-lives breaks down the risks, benefits, and technical impact — so you can choose the rollout method that protects uptime and supports growth.

👉 Big-Bang vs Phased ERP Go-Live: Which Is Right for Your SMB?

🔄 Not sure whether to choose Cloud ERP or stick with On-Premise?

You’re not alone. This guide unpacks the core differences in cost, control, scalability, and security — with detailed insights and real-world comparisons built for IT leaders and growth-focused operations teams.👉 Cloud ERP vs On-Premise: Key Differences Explained

🔩Choose the Right ERP System to Streamline Your Factory and Scale with Confidence

Discover ERP systems built specifically for manufacturers — with powerful features for shop floor control, inventory accuracy, and production scheduling. Compare usability, pricing, and industry fit in one expert-curated guide.👉The 10 Best Manufacturing ERP Software Tools for Efficiency

🔄 CRM vs ERP: What’s the Difference & Which Do You Really Need?

Confused between CRM and ERP? You’re not alone. This guide breaks down the real differences, use cases, and ROI impact — with deep analysis and real-world examples designed for operational and growth-focused decision-makers.👉 CRM vs ERP: What’s the Difference & Which Do You Really Need?

🔄 What Is ERP? A Complete Guide for SMBs (No Fluff)

Learn everything about ERP systems — how they work, core modules, real-world use cases, benefits, costs, and how to choose the right one for your growing business.👉 Master ERP from A to Z — No Need to Read Another Guide

🔄 The 7 Best ERP Systems for Large Enterprises

Expert-vetted list of powerful ERP platforms built to handle global operations, complex workflows, and enterprise-grade integrations at scale.👉 Discover Which ERP System Powers Leading Enterprises

🔄 The 7 Best ERP Tools for Small & Mid-Sized Businesses

Find easy-to-use, scalable, and affordable ERP platforms made for growing SMBs — with features, pricing, and integrations compared in detail.👉 Choose the Right ERP System to Fuel Your Business Growth

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0