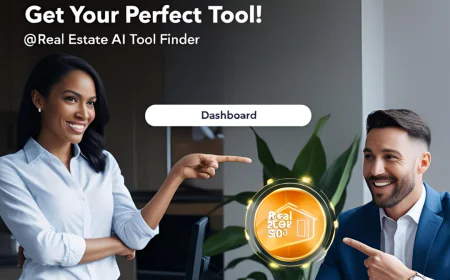

AI vs RPA in Warehouse Automation

Compare AI and RPA for warehouse tasks. Discover which one saves time, cuts costs, and scales better with expert insights, real-world use cases, and implementation hacks.

Warehouse automation has become a necessity, not a luxury. But for decision-makers in logistics and supply chain management, one key dilemma remains:

Should you invest in AI or RPA to automate your warehouse operations?

This guide gives you an ultra-detailed breakdown of both technologies in the logistics context — with insider hacks, hidden benefits, and decision shortcuts.

Understanding the Core Concepts

What is RPA in warehouse automation?

RPA (Robotic Process Automation) uses software bots to handle repetitive, rule-based digital tasks. In warehouses, this includes:

-

Updating inventory records

-

Creating shipping labels

-

Entering order details into ERP/CRM

-

Sending notification emails

-

Copy-pasting data between apps

RPA does not “think” — it simply mimics human clicks and keystrokes, fast and without fatigue.

Insider Hack: You can deploy a working RPA bot in under 5 days if you use no-code tools like UiPath, Power Automate, or Zapier.

What is AI in warehouse automation?

AI (Artificial Intelligence) mimics human intelligence. It makes decisions based on past data and improves with experience. In warehouses, AI powers:

-

Demand forecasting

-

Intelligent inventory replenishment

-

Computer vision for sorting and picking

-

Delivery route optimization

-

Anomaly detection in supply flows

Secret: AI doesn’t always need custom models. Amazon Forecast, Google AutoML, and Azure AI offer pre-trained models you can plug into your system.

How is AI different from RPA in logistics?

-

RPA is rule-based: “If this, then that.”

-

AI is dynamic: it learns from data to predict, decide, or adapt.

Example:

-

RPA sends a shipment confirmation when an order status is marked “Delivered.”

-

AI analyzes delays, predicts which orders might be late, and reroutes trucks accordingly.

Key Point: RPA follows orders. AI gives suggestions and learns.

💡 Real-World Warehouse Use Cases

How can RPA be used in a warehouse today?

-

Auto-generate invoices based on ERP entries

-

Sync CRM data between systems

-

Extract order details from emails

-

Auto-update Excel sheets with shipment logs

-

Batch-process barcode data uploads

Pro Tip: Use RPA to glue disconnected systems. It saves time when you can’t afford full integrations.

What are some high-impact AI applications in warehouse operations?

-

Predict stockouts before they happen

-

Optimize shelf space dynamically

-

Detect errors in picking based on camera feeds

-

Learn customer demand trends and adjust inventory

-

Improve workforce scheduling based on historical productivity

Hack Nobody Talks About: Use AI to analyze forklift routes inside the warehouse and reduce total movement time — leading to measurable cost savings.

Can RPA and AI be used together?

Yes — and when combined, they’re incredibly powerful.

-

AI identifies a pattern (e.g., a surge in returns).

-

RPA launches corrective workflows (e.g., freeze certain SKUs, notify managers, trigger refunds).

Pro Secret: Use AI to trigger RPA bots automatically for intelligent exception handling.

📊 Cost & Scalability Comparison

Which is more affordable: AI or RPA?

-

RPA is cheaper to start – low development cost, fast deployment, minimal data required

-

AI is expensive upfront – but brings higher long-term returns via optimization

Hidden Cost Insight: AI needs clean, labeled data. If your warehouse data is messy, expect added costs in data cleaning before AI can work well.

Which one scales better with your logistics business?

-

RPA scales horizontally (more bots = more processes)

-

AI scales vertically (smarter decisions = more automation per task)

Smart Strategy: Start with RPA to eliminate repetitive tasks, then use AI to refine processes based on the results.

🛠️ Implementation Challenges & How to Overcome Them

What are the common mistakes when implementing RPA in logistics?

-

Automating a broken process without fixing it first

-

Skipping exception scenarios (e.g., what if an email field is blank?)

-

Not involving the operations team in bot design

Pro Tip: Run a shadow-mode test for every RPA bot — let it run alongside a human to catch gaps before full deployment.

it is Recommended to read this article: Why 90% of Warehouse Automation Projects Fail (And How to Avoid It)

What hurdles should you expect when using AI in a warehouse?

Implementing AI in a warehouse isn't plug-and-play — there are several challenges to prepare for:

-

Poor data quality: AI relies on structured, clean, labeled data. Many warehouses have fragmented or inconsistent datasets, making it difficult to train effective models.

-

Inexperienced AI teams: Without data scientists or ML engineers familiar with logistics, implementation often fails or produces inaccurate results.

-

Lack of explainability: AI decisions can seem like a black box. Warehouse managers may hesitate to trust recommendations they don't fully understand.

-

Long training and testing cycles: Unlike RPA, AI systems need time to train on historical data, validate outputs, and improve accuracy — delaying ROI.

Pro Hack: Use a human-in-the-loop setup. Let supervisors review or override AI suggestions in the early stages. This builds trust, ensures safety, and helps the model learn from real-world feedback.

⚙️ Which One Should You Choose First?

When should a warehouse start with RPA?

Go for RPA if:

-

You have clear, repetitive digital workflows

-

Your systems are not integrated

-

You need automation fast (under 4 weeks)

-

You lack deep technical talent

RPA is best for:

-

Shipping updates

-

Back-office tasks

-

Admin work like HR forms or expense uploads

When is AI the better first step?

Choose AI if:

-

You already collect a lot of structured data

-

You want to predict, not just automate

-

You need smarter resource allocation or routing

-

You're focused on optimization, not just speed

AI is best for:

-

Demand prediction

-

Labor forecasting

-

Warehouse traffic management

🧠 Expert Tips & Little-Known Hacks

What are some AI hacks no one talks about in logistics?

-

Use historical weather data + shipment data to forecast delays

-

Run AI on camera footage to detect unsafe behaviors (e.g., forklifts speeding)

-

Apply reinforcement learning to optimize picking routes daily

-

Integrate AI with chatbots to handle customer inquiries automatically

What are advanced RPA tricks that improve warehouse productivity?

-

Schedule bots to auto-update ERP nightly — prevents human error during the day

-

Use bots to check vendor tracking portals and pull updates into your system

-

Deploy RPA for onboarding new SKUs — fill in catalog entries, meta info, and specs automatically

🔄 Transitioning from RPA to AI: A Growth Strategy

Is it possible to evolve from RPA to AI?

Yes — and this is a recommended pathway:

-

Start with RPA to cut manual effort

-

Analyze RPA logs to identify bottlenecks or patterns

-

Feed that data into AI models to make proactive decisions

-

Replace static RPA rules with dynamic AI triggers

This way, your automation grows from dumb execution to smart orchestration.

How do top logistics firms approach automation?

-

Amazon uses AI-driven Kiva robots for shelf-picking and real-time stock management

-

DHL combines RPA for backend processing with AI for route optimization

-

Maersk uses AI to predict shipment delays and RPA to send notifications

Benchmark Insight: They rarely pick one. The magic is in orchestration.

You Conclude:

-

Use RPA to get quick wins in warehouse admin

-

Use AI to unlock deep operational intelligence

-

Combine both for exponential results

Bonus Tip: Measure automation success by time saved, errors reduced, and decision quality improved — not just cost.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0